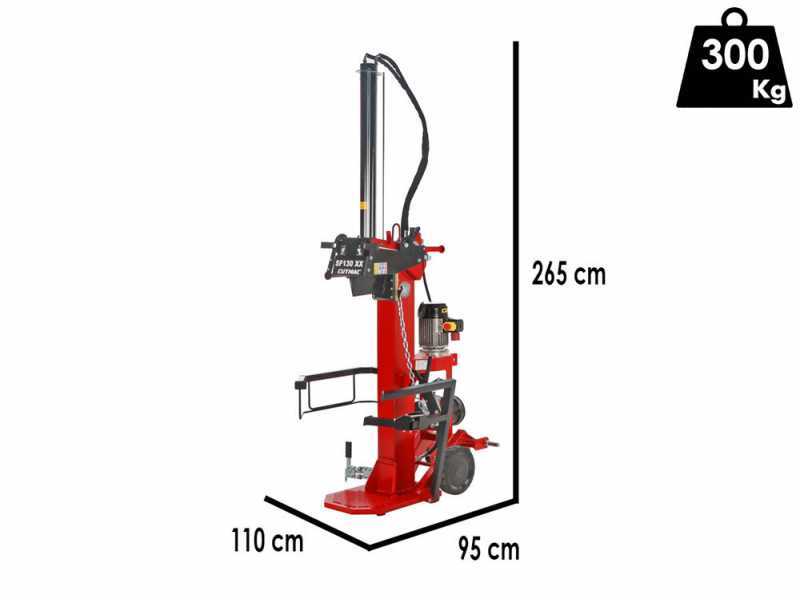

The SF130 380 + PTO XX log splitter model stands out on the market thanks to its meticulous design, aimed at satisfying the demands of the most demanding users in the woodworking sector. This machine expresses a higher level of precision and strength, ensuring optimal performance in terms of efficiency and safety during splitting operations.

Main Technical Details of SF130 380 + PTO XX (Vertical Orientation):

-

CYLINDER STROKE: The device boasts a cylinder stroke of 100 cm, making it possible to manipulate logs of various sizes. This eliminates the need for preliminary work on the workpieces, significantly simplifying the cracking process.

-

Cutting height: Thanks to a cutting height of 121 cm, it is also able to process large logs, without the need for preliminary cutting interventions.

-

Oil capacity: The machine has an oil tank with a generous capacity of 21 litres, thus allowing prolonged working sessions, minimising interruptions and guaranteeing a constant and fluid flow in splitting operations.

-

Adjusting the Stroke of the Column:: This unique functionality allows operators to customize the machine according to the specific dimensions of the logs to be machined, thus ensuring a higher degree of precision in splitting operations.

-

Thrust Force: Characterized by a thrust force of 13 tons, it stands out for its robustness and power, representing an essential tool for those looking for efficiency and reliability in wood treatment.

To further increase its value, the SF130 380 + PTO XX is equipped with a patented system that facilitates cylinder locking and unlocking, making operation quick and efficient.