The powerful Bull SPLET20 log splitter made by Ceccato Olindo is the ideal choice for those who require a durable and reliable working tool for intensive professional use.

This tool is characterised by its robust wedge and a thick steel guide, ensuring superior protection of the machine cylinder even under the most stressful situations.

The versatility of the Bull SPLET20 is evident in its ability to operate either on electric power, thanks to its powerful 7.5 Hp three-phase electric motor, or via a Cardan shaft connected to a tractor power take-off.

With a piston stroke of 110 cm, it is further distinguished by its ability to operate at double speed, simply by adjusting the pressure on the levers.

This log splitter is capable of generating an impressive thrust force of 20 tonnes, making it suitable for splitting knotty logs of various sizes, up to a maximum height of 114 cm and a diameter of 65 cm.

In terms of safety, the Bull SPLET20 is equipped with a robust safety arch, an automatic adjustable limit switch control system and all the necessary safety devices to ensure operator protection.

These features not only make the Bull SPLET20 highly effective, but also extremely safe for professional use.

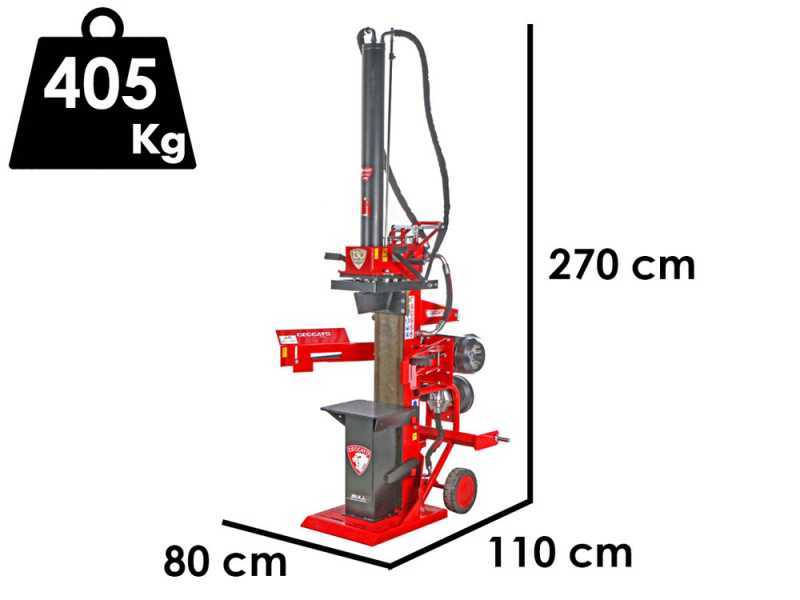

In addition, the piston is designed to be foldable, making it easy to store and adapt the log splitter to available space. Made entirely in Italy, Ceccato Olindo's Bull SPLET20 belongs to the prestigious Bull line of log splitters.

This model is not only an example of extraordinary quality and efficiency, but also a symbol of Italian durability and reliability in the professional log splitter sector.