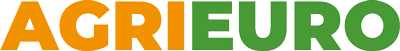

The AR 32024 C pump is a professional solution designed for low pressure systems, ideal for agricultural and industrial applications requiring high liquid volumes under demanding operating conditions.

Thanks to its three-diaphragm BlueFlex™ technology, this pump ensures reliability, efficiency, and long-lasting performance.

Equipped with a Rilsan-coated aluminium body and stainless steel AISI 303/304, it resists chemical agents and corrosion. The pumping unit operates with a maximum flow rate of 128 l/min (33.8 gpm) and reaches a pressure up to 20 bar (290 psi), with a power consumption of 6.8 HP at 550 rpm.

It is therefore perfect for spraying with booms, atomisers, fertiliser treatments, and livestock washing.

The structure is completed by an oil bath mechanism with a transparent tank for visual level control, spherical profile valves to reduce pressure losses, and an air-oil damper to decrease water hammer effect, ensuring a smoother and more regular flow.

The pump is prepared for the remote level sensor and the remote oil tank installation kit.

The NBR seals make it compatible with a wide range of liquids, while the reinforced feet, cardan protection, and Geomet fastenings ensure stability and robustness.

The presence of the “oil cushion” system with ring pistons improves diaphragm protection, extending the machine's service life.

The AR 32024 C is the ideal choice for those seeking a three-diaphragm sprayer pump capable of combining high performance, low maintenance, and durability even in the most intensive use contexts.

NOTE:

If products containing mineral substances such as Kaolin; Zeolite; Basalt etc. are used... To avoid compromising the internal components of the pump in the long term, it is advisable to perform washes at the end of each treatment and at the end of each season, disassemble some parts of the pump such as valves, heads, and membranes, for cleaning any residues that have accumulated from minerals.

These procedures will ensure a long pump life even if the above minerals are used.