The quality of AgriEuro wood-fired ovens provides you with a great cooking experience and ease of use (which is not guaranteed by all wood-fired ovens) Our wood-fired ovens are functional, effective, durable and aesthetically pleasing! Main features:

- The wood consumption: only 4 kg of wood will be enough for several cookings!

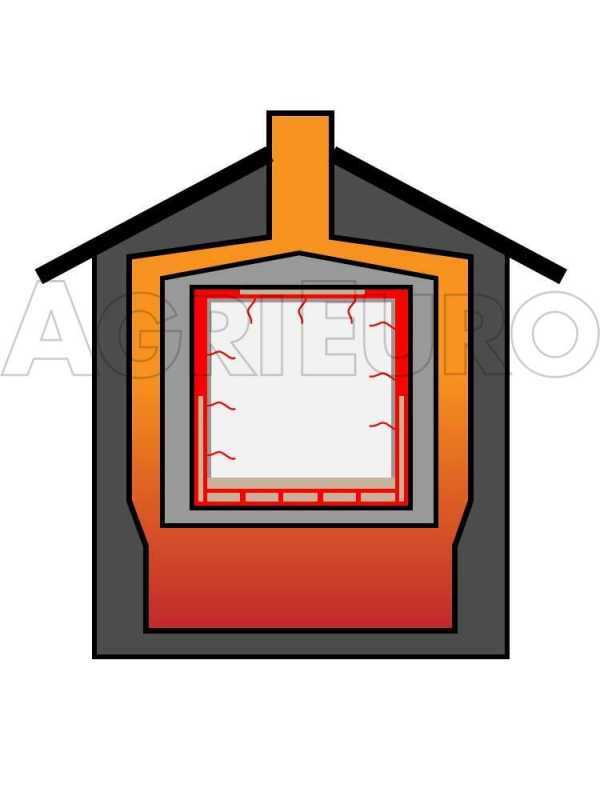

- The convenience and hygiene given by the separation of the cooking and combustion chamber.

- Food does not directly touch the ash and embers, nor wood (often dirty or polluted) or smoke that can make it even carcinogenic

- Easy cooking and oven heating thanks to the separation and autonomy of the two chambers

- The cooking times, as it takes less time to reach the cooking temperature

These important aspects are complemented by the great advantages of wood-fired cooking: unparalleled in flavors and fragrance, natural and extremely low in fat. Size and features of this model:

- 3 cooking floors

- cooking chamber depth: 100 cm

- cooking chamber width: 50 cm

- cooking chamber height: 50 cm

- Weight: 450 kg

This model belongs to the category of large-sized ovens.

Cooking capacity: 70 servings